- Davada Engineering,Shapur Road, Mangrol, Gujarat.

- info@shreefreezings.com

- +91 98255 05065

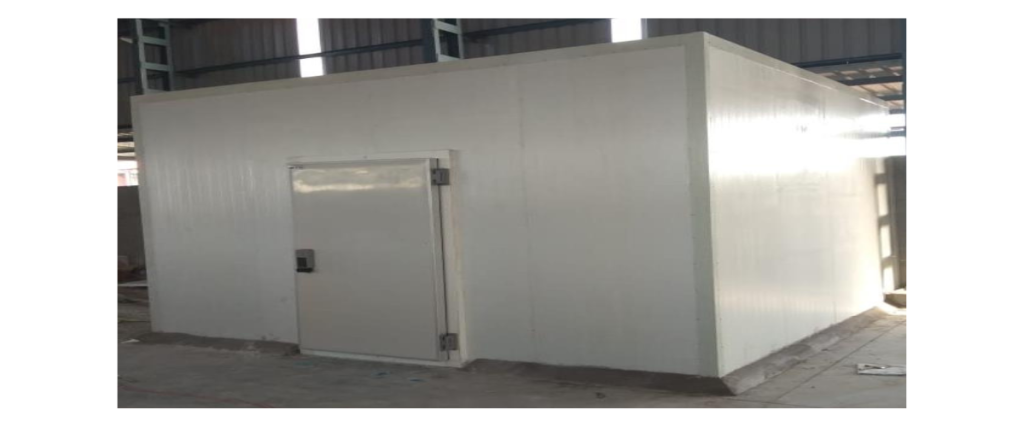

We are a leading name in the industry, engaged in offering classic range of cold Room to our clients. This product range is manufacturing using premium quality range of material vendors. This product range is available at market competitive price.

Range of cold Rooms:

PIR PUFF Panel Thickness (mm): 50,75,100,150

Temperature: +15’C to -45’C

Panel Surface Material: FRP Sheet

Sheet Thickness: 1.5 to 2.5 mm

Floor insulation: – Kota Panel, PIR Puff Slab with FRP Cladding, FRP Sheet

Type of Cold Rooms: Single Chamber Cold Room Multi Chamber Cold Room

Flooring: PIR PUFF Slab and FRP Flooring

Temperature range: +2’C to +5 ‘C

We Manufacturing Cold Room that are made by advanced technology used for preserving food items like Dairy Products, fast foods, Frozen food, sea food, Fruits & Vegetables, dry fruits, mineral water etc… consuming less energy.

Technical specification & special features:

Thickness: 50,75,100,150

Surface Material: – FRP Sheets

Floor:

For kota Stones or concrete Floor, PIR Puff Slab with both side tarfelt

coated.

Frp Lining on ply Sheet.

Door:

Temperature: – 45’C to +20’C

We Manufacturing Cold Room that are made by advanced technology used for preserving food items like Dairy Products, fast foods, Frozen food, sea food, Fruits & Vegetables, dry fruits, mineral water etc… consuming less energy.

Technical specification & special features:

Thickness: 50,75,100,150

Surface Material: – FRP Sheets

Floor:For kota Stones or concrete Floor, PIR Puff Slab with both side tarfelt coated. Frp Lining on ply Sheet.

Door: Temperature: – 45’C to +20’C

We Manufacturing Cold Room that are made by advanced technology used for preserving food items like Dairy Products, fast foods, Frozen food, sea food, Fruits & Vegetables, dry fruits, mineral water etc… consuming less energy.

Technical specification & special features:

Thickness: 50,75,100,150

Surface Material: – FRP Sheets

Floor: For kota Stones or concrete Floor, PIR Puff Slab with both side tarfelt coated. Frp Lining on ply Sheet.

Door:Temperature: – 45’C to +20’C

Cold Room are delivered as complete units easy to mount with all fitting, Sliding rail and bottom guide roller etc.. SFM offers three types of door as a wide choice for customers. Swing Door, Hinged Door, Sliding Door, Section Door, Service hinged Door, Dock Leveler, Dock Shelter, PVC Strip Curtain, High Speed Door, Fire Door For Shree Freezing & Marketing. These doors are PIR PUFF Insulated Door and designed for tough commercial environments such as cold stores, Incubation Chamber and Blast Chiller. These doors are made using best quality accessories for rough and tough usage.

Application: Cold Room.

Usage/ Application: Food Industry

Design/ Pattern: Standard

We are one of the leading manufacturing of Refrigeration Units such as evaporator units, condensing units both waters cooled and air-cooled and control panels for cold rooms. These are specially designed for cold rooms which makes them give the desired efficiency and protect your products in controlled temperature. Capacity As per your requirements.

Usage: Industrial Isa, Commercial Use.

Application: Cold Room

Individual Quick Freezing Tunnel Freezers precisely freeze and chill wide range of bulk products for the food processing industry. Capable of handling 0.5 to 2.5 tons per hour, tunnel freezer ensure the highest degree of IQF quality and supreme freezing flexibility.

Features:

• Gentle mechanical fluidization

• Broad range of bulk, flat or fragile products.

• Modular design

• Impingement design

• FRP Construction

• Ample areas for service & cleaning

• Frost management system’

• Multiple temperature zones

• Energy efficient design

Freezing into blocks is an effective economical method of preserving, handling transporting and storing perishable products. Horizontal Plate Freezer in one easy operation, ideal for freezing fish, offal’s, fruit puree, fish fillets, shrimp and vegetables.

We are used to freeze flat products, such as pastries, fish fillets, and beef patties, As well as irregular- shaped vegetables that are packaged in brick-shaped Containers, such as asparagus, cauliflower, spinach, and broccoli. The food is Firmly pressed between metal plates that are cooled to subfreezing Temperatures by internally circulating refrigerants

Products are simply placed into horizontal pockets between the aluminum freezing plates. After freezing, the blocks can be unloaded manually or mechanically onto pallets or a conveyor system and within minutes the whole processing cycle can begin again.

Using IQF technology will significantly reduce the ice formation on the product, Due to the fact that the product is frozen fast this leads to much smaller ice Crystals compared to cold Store Freezing. Slow freezing causes large ice crystals to Form and this affects the integrity of cells, stretching the membrane, the larger The crystals the more damage the product will suffer. The deterioration is Irreversible, meaning that the texture of the product will not return after thawing. With IQF there is a minimal formation of ice crystals and this will help the product Keep its texture until first defrost.